The demands on order fulfillment centers are higher today than ever before. With the rapid growth of e-commerce, the pressure to process orders faster and more precisely is also increasing. At the same time, the lack of qualified workers is a significant challenge. This is where the PickCenter RovoFlex from TGW Logistics comes in - a solution that compensates for the labor shortage, stabilizes processes and gives our customers a clear competitive advantage.

Compensate for labor shortages, secure order picking performance

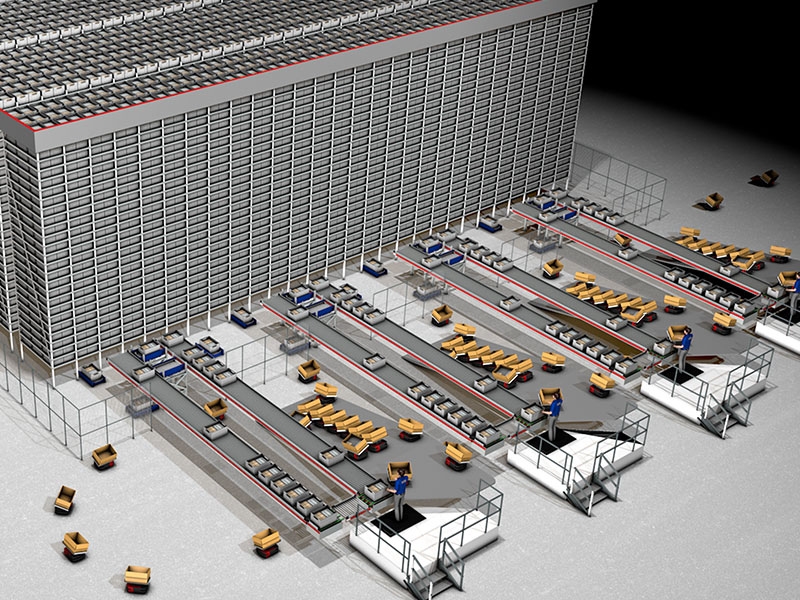

The operators of order fulfillment centers face the constant challenge of finding and retaining qualified personnel for order picking. This shortage affects the ability to process orders on time and with the desired quality. The PickCenter RovoFlex from TGW Logistics solves this problem with its high level of automation capability. It compensates for personnel bottlenecks and ensures stable, reliable order picking performance - regardless of the availability of human workers.

Hybrid picking for maximum flexibility

The PickCenter RovoFlex from TGW Logistics combines advanced robot technology with an intelligent camera system, offering a hybrid picking station. This enables our customers to switch seamlessly between manual and automatic picking. This is a decisive advantage, especially during peak times such as the Christmas season. RovoFlex can handle even high order peaks with a throughput of up to 1,000 picks per hour - regardless of whether it is food, fashion items or industrial goods. Thanks to standardized components and the robot's low weight, it can be used in a variety of situations outside of the PickCenter. For example, other workstations as an extension of existing systems, but also outside of order processing. Processes such as sorting, consolidation or separation are thus efficiently automated.

Round-the-clock use and increased efficiency

A significant advantage of the PickCenter RovoFlex from TGW Logistics is its ability to work around the clock. While human workers need breaks, RovoFlex remains in continuous use. This significantly increases picking performance, especially during the night shift, while reducing personnel costs. In addition, upstream tasks such as consolidation and housekeeping can be efficiently automated, which further increases productivity in the warehouse.

Fast return on investment (ROI)

RovoFlex from TGW Logistics scores not only with performance, but also with cost-effectiveness. Compared to other systems, there are no high annual license costs, which shortens the amortization of the acquisition costs to just 1.5 years. This makes RovoFlex an outstanding choice not only technologically, but also financially.

Artificial intelligence as an efficiency booster

At the heart of the RovoFlex system from TGW Logistics is artificial intelligence (AI), which turns the robot into a learning, autonomous helper. The AI continuously optimizes the picking process, minimizes errors and maximizes productivity - without the need for human intervention.

Easy integration into existing systems

RovoFlex can be integrated into existing systems with minimal effort - a decisive advantage in retrofit and modernization projects. Our customers can integrate the picking robot into their systems within a few days and immediately benefit from the advantages of automation.

Conclusion

TGW Logistics' PickCenter RovoFlex is more than just a picking system. It is the answer to the biggest challenges facing order fulfillment centers today. With automation, flexibility and efficiency, RovoFlex helps overcome labor shortages, manage order peaks and increase productivity. The fast ROI and easy integration make RovoFlex a future-proof investment. In a world where speed and precision count, TGW Logistics' RovoFlex is the key to success.