Automatic storage and retrieval machines

Innovation

based On

Tradition

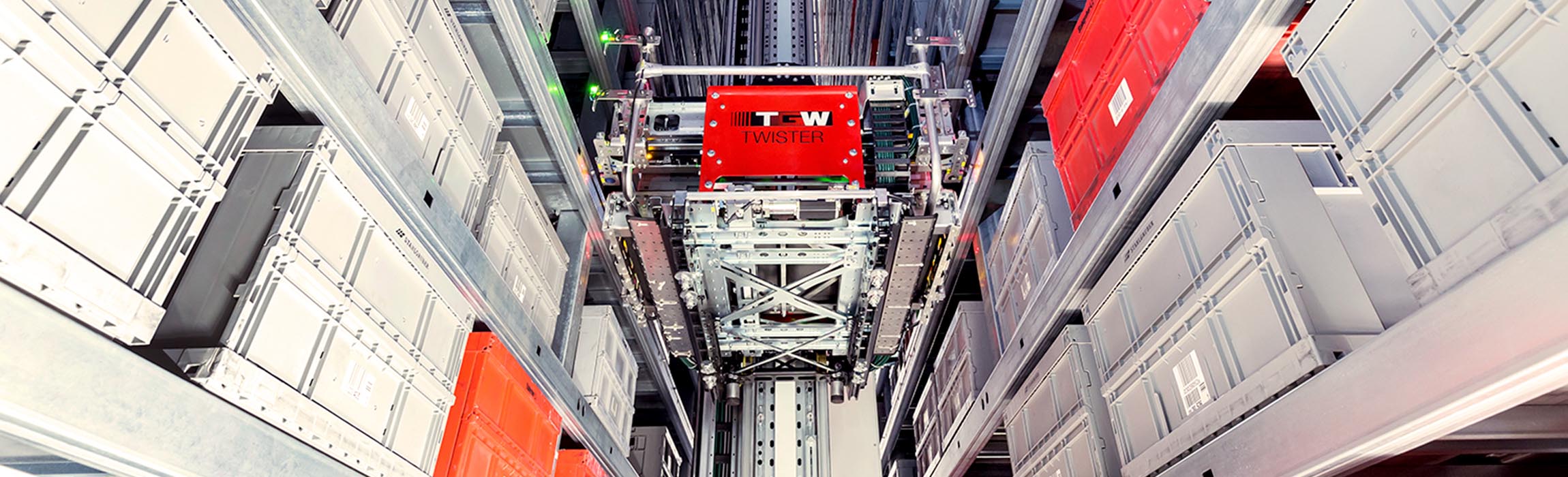

As a pioneer in the development of automatic mini-load warehouses, we have created highly integrated, complete mechatronic concepts which consist of the software, hardware and mechanical system. On the cutting edge of storage and retrieval machines, more than 8,000 products are already being used around the world as part of different complete solutions. They store and transport millions of cartons and totes – reliably and at peak performance.

In addition to the powerful mechanical system, sophisticated control software and intelligent drive technology, our highly dynamic automatic mini-load warehouse modules set themselves apart with simple operations and extremely low maintenance.

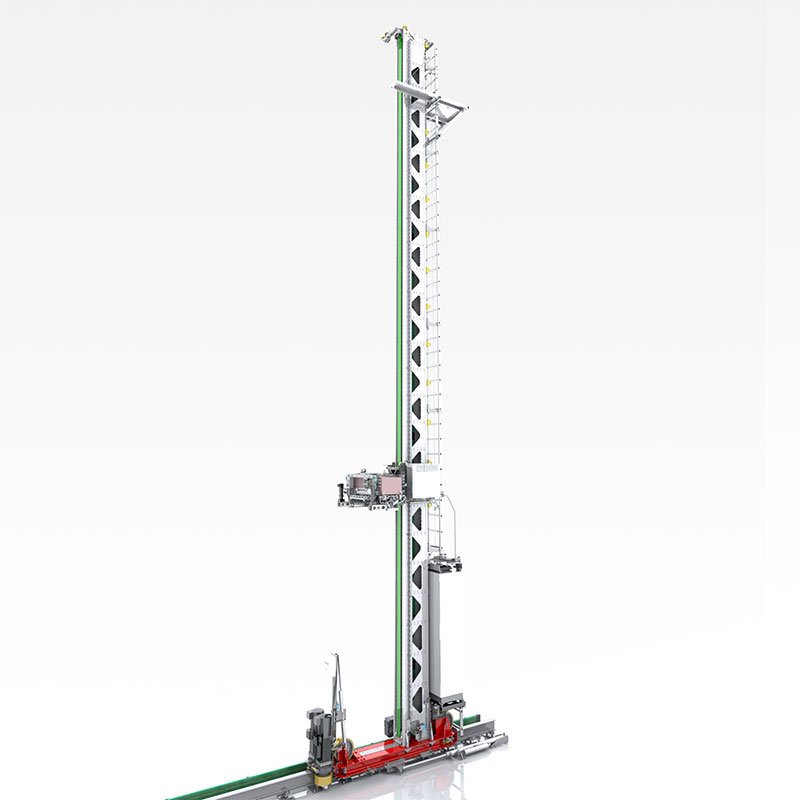

Our comprehensive product modules for automatic mini-load warehouses, allow for flexible adaptation to your individual requirements. The highly dynamic storage and retrieval machines as well as load handling devices offer maximum flexibility, for a height range from 4 to 25 metres and a payload of up to 100 kilograms.

Good

to

know

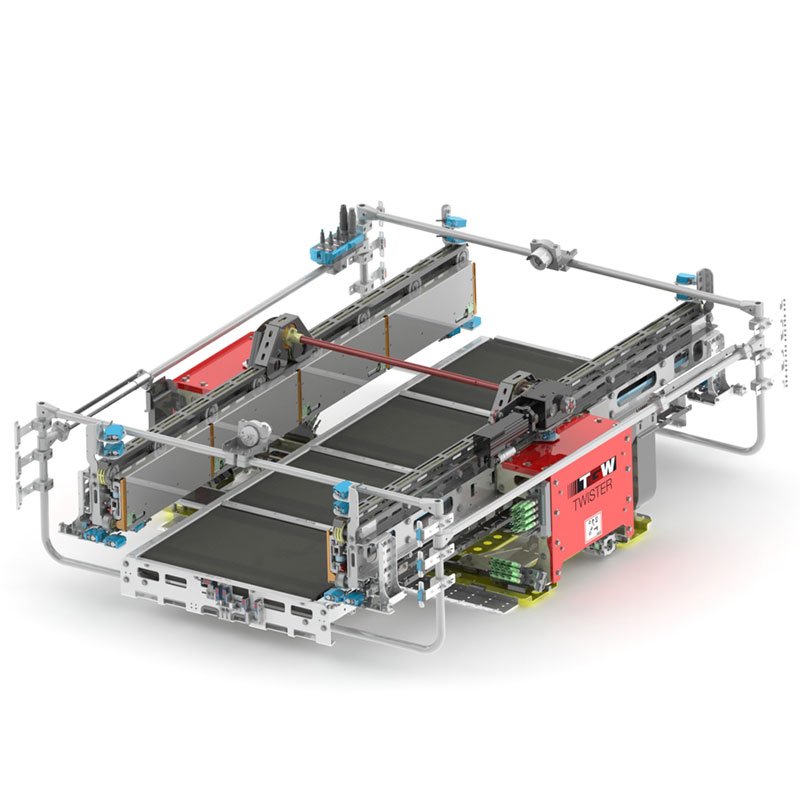

SPACE-SAVING MODULE SOLUTION Thanks to multi-deep storage of different loads up to a payload of 100 kg

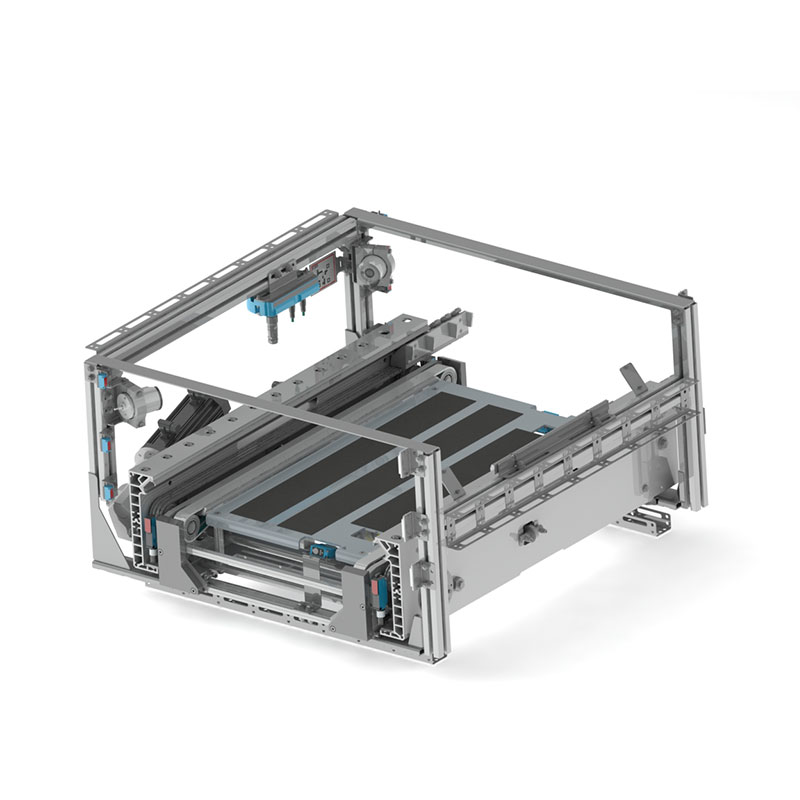

CONSTANT OUTPUT full lifting load and dynamics in all height ranges

ENERGY EFFICIENCY Thanks to optimised movement sequences and regeneration of brake energy recovery

DURABLE TECHNOLOGY Thanks to decades of experience in development, maintenance and successful operation of systems

EFFICIENT COMMISSIONING All main components are thoroughly tested in advance

ROBUST Even suitable for use under extreme environmental conditions (e.g. freezer area)

did you

know?

As a pioneer in the industry, we have played a major part in shaping the technology standards for masts, friction wheel drives and timing belt lifting units. We are also the technology leader in the field of direct carton storage. Our current product range for storage and retrieval machines is based on over 40 years of experience. Our Commissioner lifting beam system and the Mustang single-mast device represent the best-engineered mini-load technology on the market.

warehouse

Product

world

Learn more about our portfolio on flexibly configurable storage and retrieval machines up to 25 metres in height, as well as high-performance lifting beam devices for fast and compact buffering and consolidation requirements.

STORAGE AND RETRIEVAL MACHINES

LOAD HANDLING DEVICES

Interested?

The following topics might be interesting for you as well – Learn more about our services and if you have any questions, contact us!