- E-Commerce and automation spur the retrofit market

- Sustainability is gaining increasing importance as a decisive criterion

- The most important success factors at a glance

(Marchtrenk, 9 February 2022) Promising faster delivery and establishing resilient supply chains is only possible with state-of-the-art intralogistics systems. Anyone planning a retrofit project needs to find a competent partner and to keep a few rules in mind.

It has now been 60 years since the opening of the first high bay warehouse (HBW). The trailblazer was Bertelsmann's "Book Silo," which went into operation in Germany in 1962. Since then, thousands of HBWs have been built and some of them have been going for decades. But whether HBWs or automated mini-load warehouses, after years in operation, practically no system still exists in the same form as when it first opened. Steel components may be sturdy, but IT and control elements as well as mechatronics must be regularly updated to the state of the art. And when product ranges, volumes or customer demands change, modernisation and expansion become inevitable.

Adjustments, expansions and modernisation

Fundamentally, retrofit activities can be divided into three subcategories: adjustments, expansions and modernisation. The first subcategory consists of measures that may need to be taken within months of a system being put into operation, in order for the company to keep up with new market requirements. Expansions are particularly important for companies that experience strong growth after go-live. And regular modernisation of the control systems and IT is generally necessary every four to five years because the technology changes. Often times the mechanical equipment is not due for renewal until after ten or more years.

E-commerce and automation

Growing online trade, increasing automation: the rising number of logistics systems means growth in the retrofit market as well. TGW now handles almost five times as many retrofit projects annually as it did ten years ago. Another important driver is the users' increasing awareness that they can only keep up with the competition if they adapt to their customers' needs. And those who promise shorter and shorter delivery times have no choice but to establish a resilient supply chain. Unplanned downtimes are a nightmare for logistics managers, and long cycle times are a clear competitive disadvantage.

Putting off retrofitting means taking risks. For one thing, spare parts could run out or technology could become unavailable. For another, knowledge is lost over the years when, for example, the IT experts who still know how to work with the programming languages C and C++ retire. The situation is similar for controls systems.

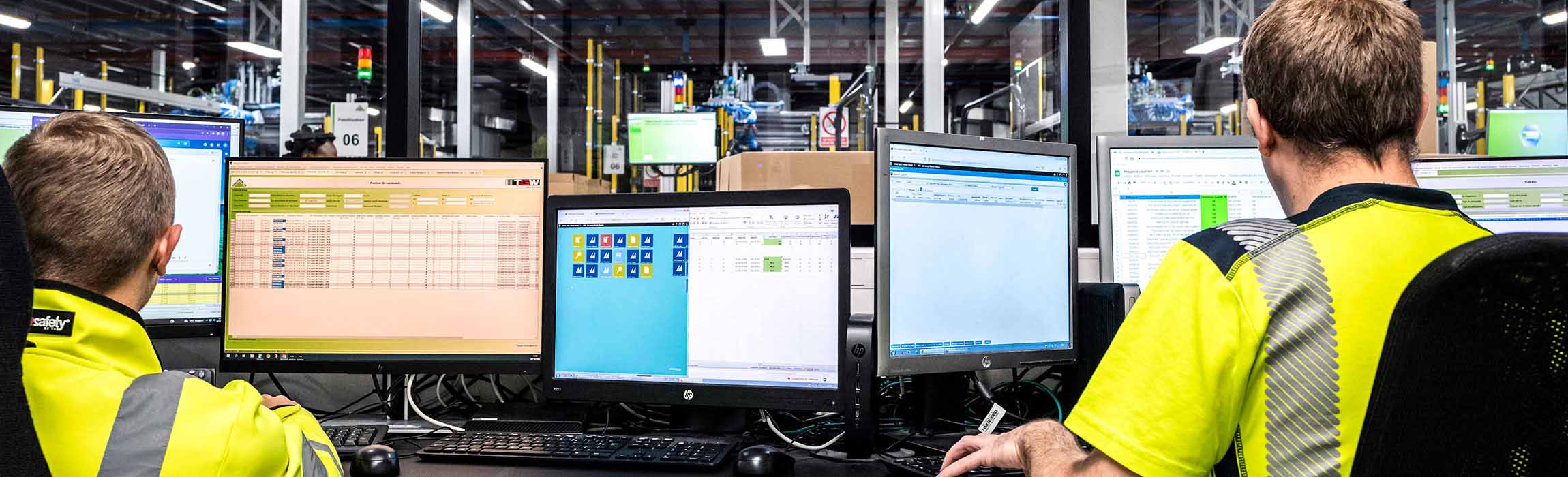

Information in real time

As the speed at which technology changes continues to increase, companies are gearing up for the future. Even just a software upgrade increases functionality. A new warehouse management system enables better connectivity and therefore a more continuous data flow. The goal is to be able to exchange information along the value added chain in real time. On top of that, with increasing regularity companies are looking to integrate autonomous technologies such as automated guided vehicles or robots into their overall system. That can only yield optimal results if the system is running on state-of-the-art technology.

Modern warehouse management systems also have the option of touchscreen controls. The advantages: they are easy to use and it does not take long to train employees. This is also true of the continuous zoom visualisation option: these days, users can zoom in down to the system's sensor level to find defective components, for example. Maintenance is also faster and easier after a retrofit and the integration of modern components that that entails.

Sustainability as a decisive criterion

Since the subject of sustainability has come to the fore in politics, society and business, it has also become one of the drivers of retrofit projects. Generally speaking, these projects are inherently sustainable investments because they not only extend the lifespan of a company's systems but also increase the company's efficiency. Many companies are pursuing ambitious programmes aimed at reducing emissions: they are more conscientious than before about resources and carefully and thoroughly examine every link in their supply chain to identify the potential for reduction. In doing so, they delve deep and compare things like the energy consumption of different storage and retrieval machines or conveyor systems.

The bottom line is, companies should not debate whether or not to undertake a retrofit, but rather when and how. Of course they have to budget for it. But what is the alternative? If the competition can fulfil customer wishes faster and better, one runs the risk of losing customers, and in this digital age the competition is no more than a click away. For example: in the past, a user would be satisfied with one delivery containing 50 order lines. Today, that customer wants the same volume delivered to ten different places, at ten different times, just as they have come to expect from the well-known B2C platforms. Looking at it that way shines a different light on investing in a retrofit and the corresponding return on investment.

TGW as an experienced partner

Once a company has recognised the need for a retrofit or an expansion, they need to find the right partner to carry it out. Over the course of its more than 52-year history, TGW has identified the central success factors for such projects. Alongside experienced project managers, a structured plan and a functional specification, defining the migration phases is an important preparatory step.

Additionally, employees need to be well trained so that the on-site specialists are also familiar with the setting. It is also important to choose the right moment for a retrofit. There are managers who assume they can wait until their systems are approaching the breaking point before thinking about it. But they are forgetting that the lead time for a project can be up to a year and is sometimes even longer now due to the corona pandemic.

TGW approaches customers when their intralogistics systems have reached 85 percent capacity so that specialists and the user can develop a solution together that will afford the desired benefits in good time. The experts also make sure that retrofit specialists possess comprehensive know-how. Moreover, the products used are specially designed for retrofits.

The seven success factors for a retrofit project

- Consider the lead time and start early enough

- Choose experienced partners and project managers

- Develop a structured plan

- Integrate specially developed retrofit solutions

- Create a comprehensive functional specification

- Clearly define migration phases

- Intensive employee training